Automated Defect Detection for Industrial Quality Control

Motivation

The use of machine learning/deep learning in industrial image-based quality control holds enormous potential, but is currently hindered by two circumstances:

- Supervised learning methods require large amounts of data, also from error-prone states, which have to be collected at high cost..

- No procedures exist that are suitable for managing the product life cycle of developed processes.

The methods and current developments in the field of Open Set Recognition offer possible solutions and are being researched in the project..

Scientific Questions

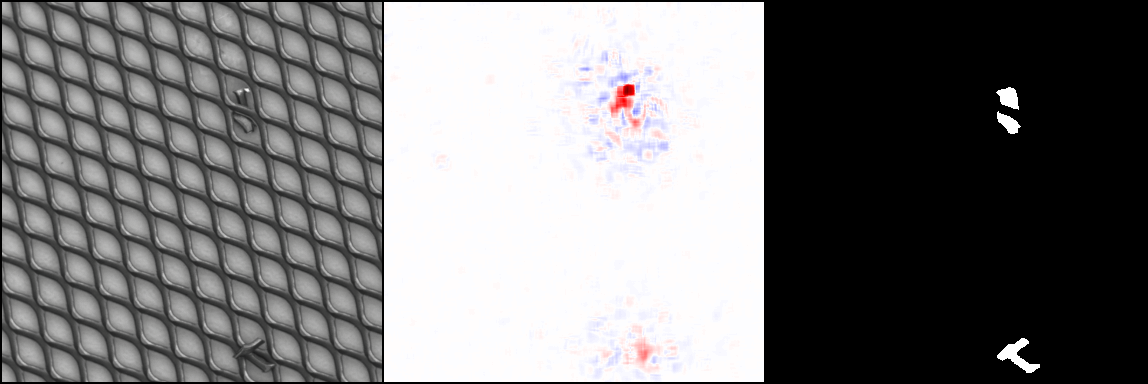

To overcome the problem of large data sets, anomaly detection algorithms are being researched and developed. In contrast to classical supervised learning methods, the goal of anomaly detection is a descriptive and discriminative description of the normal state.

Algorithms are developed on the public MVTec dataset and also adapted to special applications, such as fault detection in complex textiles (AiF project OnLoomPattern).

As a basis for the development of methods for product lifecycle management, methods of out-of-distribution (OOD) detection are being researched and further developed. In combination with explainble AI (XAI) algorithms, these allow on the one hand the automatic assessment of whether a machine learning system may be used (OOD), and on the other hand the verification of the automatic assessment (XAI). Furthermore, the algorithms are adapted to the special use case of the forgery-resistant animal hair fiber determination (AiF project KiT).

Theses

New theses are regularly advertised in the area of Automated Defect Detection for Industrial Quality Control. In addition to the general overview, there are also numerous topics that have not yet been advertised, which will be gladly presented in a personal conversation.

Partners

- Prof. Dr. Thomas Gries, Chair of Textile Engineering, ITA – Institute for Textile Technology, RWTH Aachen University

- Prof. Dr. Andreas Herrmann, Vice Scientific Director, DWI – Leibniz Institute for Interactive Materials, Aachen

External Funding

- AiF – German Federation of Industrial Research Associations, “Automatic real-time defect detection in textiles with complex pattern structures- OnLoomPattern”, Project nr. AiF 19811 N

- AiF – German Federation of Industrial Research Associations, “Integrative measuring system for defect detection during textile surface production”, Project nr. AiF 355 Z

- AiF – German Federation of Industrial Research Associations, “Artificial intelligence for automated, forgery-resistant identification of animal hair”, Project nr. AiF 21376 N

Contact

Publications

Address

Lehrstuhl für Bildgebung und BildverarbeitungRWTH Aachen University

Kopernikusstraße 16

52074 Aachen Germany

lfb@lfb.rwth-aachen.de

+49 241 80 27860

By continuing to use the site, you agree to the use of cookies. more information

English translation below.

Die Cookie-Einstellungen auf dieser Website sind so eingestellt, dass sie "Cookies zulassen" sollten, um das bestmögliche Surferlebnis zu erhalten. Sie können diese Website weiterhin nutzen, ohne Ihre Cookie-Einstellungen zu ändern, oder Sie klicken unten auf "Accept" und stimmen der Nutzung der Cookies zu.

In den Cookies werden lediglich die von Ihnen gewählten Spracheinstellungen gespeichert. Bitte lesen Sie auch unsere Datenschutzerklärung.

The cookie settings on this website are set to "allow cookies" to give you the best browsing experience possible. If you continue to use this website without changing your cookie settings or you click "Accept" below then you are consenting to this.

Only your chosen language settings are stored in the cookies. Please also read our privacy policy.